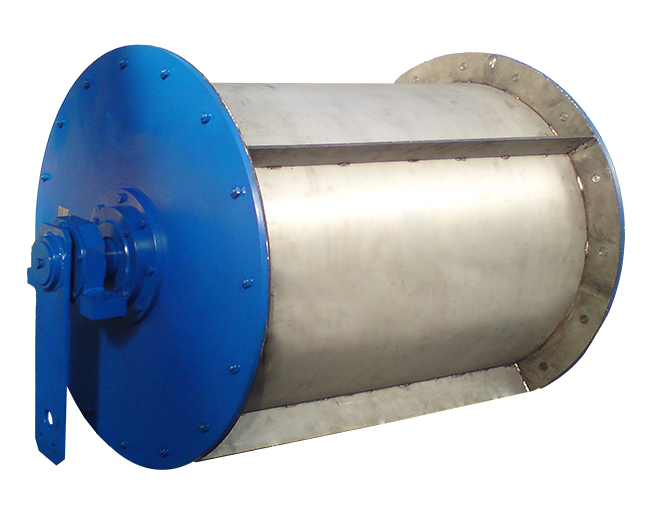

Magnetic drum separator DrumMag

- Permanent magnetic system with intensity from 0.08 to 1.0 Т

- Efficient recovery of magnetic inclusions with size from 300 mm to 0.02 mm

- Automatic cleaning

- Operation temperature range from -50°С to +50°С

- Operation with abrasive materials

- Easy installation and operation

- Certificate of conformity to requirements of (technical regulations of the Customs Union) TR CU

Product Description

Self-discharging DrumMag magnetic drum separator is installed at points of material discharge from conveyor belt or vibrating feeder, providing continuous high quality removal of magnetic impurities from dry bulk flow.

Efficient recovery of magnetic inclusions with size from 300 mm to 0.02 mm

The drum magnetic field intensity value determines its efficiency for removal of metal inclusions:

– from 0.08 to 0.24 T (from 800 to 2 400 Gauss) for obtaining a saleable product from slag dumps; processing of ferrous scrap up to 150 mm; cleaning raw materials from hardware, tramp metal or shredded tires from the cord. DrumMag protects crusher and shredder from damage and premature wear.

– from 0.24 to 0.6 T (from 240 to 6 000 Gauss) for upgrading quality of raw materials by removal of small magnetic inclusions (metal rubbings, scale, etc.) with grain size up to 0.02 mm. DrumMag iron separator with this induction is most effective in processing of ores and nonmetallic materials with medium magnetic susceptibility (ferrous slags, iron, manganese, chromium and other ores).

– up to 1 T (up to 10,000 Gauss) for maximum cleaning of material from magnetic inclusions with size up to 0.02 mm, including weakly magnetic (manganese and stainless steels), thereby increasing the end product value. DrumMag guarantees the production of high-quality material with minimum content of contaminants in processing of ore and nonmetallic materials with weak magnetic susceptibility (titanium-zirconium, calumbite-tantalite, oxidized and carbonate iron ores, etc.).

Automatic cleaning

Cleaning of raw materials from magnetic impurities is automatic without personnel involvement.

Continuous removal of magnetic inclusions in automatic mode improves separation quality compared to separators with mechanical or manual cleaning (PlateMag 2). Special design of ribs minimizes material carryover into the magnetic fraction.

Operation temperature range from -50°С to +50°С

Reliable magnetic system and simple design of the separator ensure its operability in a wide temperature range from -50°С to +50°С.

DrumMag provides effective work in any weather conditions, indoors and outdoors.

Operation with abrasive materials

The separator operating surface is made of durable abrasion-resistant chrome-nickel steel. In case of operation in highly abrasive medium, the separator shell is additionally lined with wear plates.

Easy installation and operation

Installation and settings of the separator are easy: the machine has two bearing surfaces, compact overall dimensions and weight.

The product has a simple and robust design with little maintenance, all materials and components are tested by long-term operation at our customers’ facilities. Compliance with operation terms provided in IOM significantly extends its service life.

Have difficulties choosing or haven’t found what you are looking for?

Please, fill in the questionnaire on our site and we will select the most suitable solution to you.