Magnetic separation is an essential technique widely Drum Separator used in various industries such as mining, recycling, and materials science. Among the many magnetic separation devices, the laboratory magnetic drum separater is one of the most crucial tools for research, testing, and small-scale processing. This device helps in the separation of magnetic and non-magnetic materials, allowing for effective material analysis and the optimization of processes before scaling up in industrial settings.

What Is a Laboratory Magnetic Drum Separator?

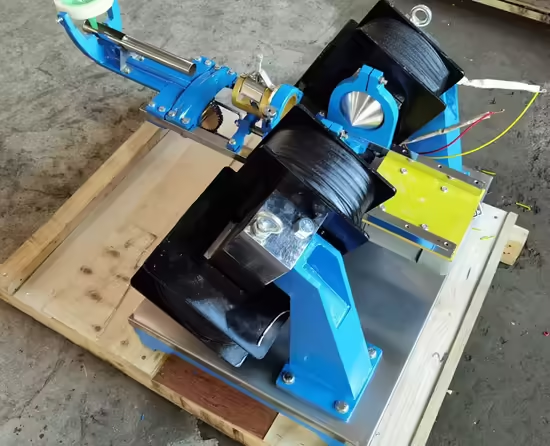

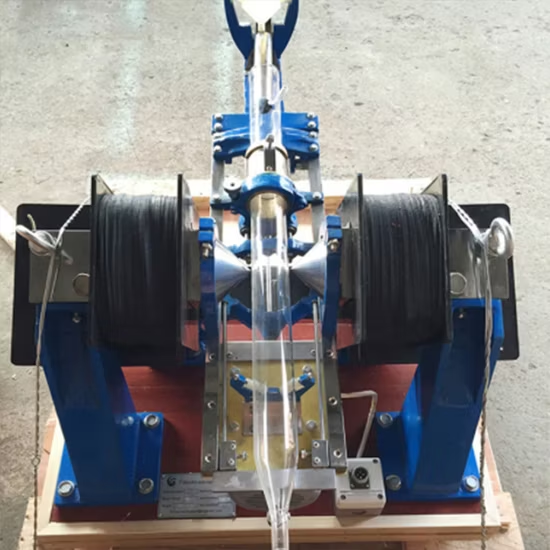

A laboratory magnetic drum separator is a small-scale, highly efficient device used to separate magnetic particles from non-magnetic substances. It is often used in laboratories to analyze the magnetic properties of materials or conduct small-scale separation experiments. The magnetic drum-separator consists of a rotating drum that is magnetized to attract and separate magnetic materials, while the non-magnetic particles continue to flow through the system.

The drum is typically powered by an electric motor and operates by creating a strong magnetic field that captures ferromagnetic or paramagnetic materials as they pass over the drum. The non-magnetic particles are then discarded, and the separated magnetic materials are collected for further analysis.

How Does a Laboratory Magnetic Drum Separator Work?

The operation of a laboratory magnetic drum separator involves the following steps:

- Feed Material: The material to be separated (often in slurry form or as dry particles) is fed into the drum-separator.

- Magnetic Field Interaction: As the material moves across the rotating drum, the drum’s magnetic field interacts with the particles in the feed. Magnetic materials (such as iron, cobalt, and nickel) are attracted to the drum’s surface, while non-magnetic materials (such as sand, minerals, and other non-ferrous metals) are not.

- Separation: The rotating drum moves the magnetic particles to a separate collection area. The non-magnetic particles are discharged from the system at the opposite end, allowing for efficient segregation.

- Collection: The separated magnetic particles are collected for further processing or analysis. The non-magnetic particles continue their path, either being discarded or sent for further treatment.

The design of the drum-separator allows for continuous operation, making it ideal for testing the magnetic properties of materials in controlled laboratory environments.

Applications of Laboratory Magnetic Drum Separators

Laboratory magnetic drum separators are used in a variety of industries and research applications, including:

1. Mineral Processing and Mining

In the mining industry, a laboratory magnetic drum-separator is used for testing ores and minerals to determine their magnetic properties. It helps to assess the feasibility of using magnetic separation for large-scale mineral extraction. It can also be used to concentrate valuable magnetic ores like magnetite and separate them from gangue materials.

2. Recycling

Magnetic separation is an important method for recycling scrap metals and other materials. A laboratory magnetic drum separator can be used to separate ferrous metals (such as iron and steel) from non-ferrous materials. This enables recycling processes to recover valuable metals for reuse in manufacturing.

3. Food and Pharmaceutical Industries

In industries where product purity is paramount, such as food processing and pharmaceuticals, laboratory magnetic drum separators can be used to remove magnetic contaminants from raw materials, ingredients, and final products. This ensures product safety and meets regulatory standards for contamination control.

4. Environmental Remediation

Laboratories use magnetic separation to clean contaminated water or soil samples, removing magnetic particles such as iron filings or pollutants that are magnetic in nature. This technique is useful for environmental monitoring and remediation projects.

5. Material Science Research

In material science, laboratory magnetic drum separators can be employed to test and study the magnetic properties of new or synthesized materials. Researchers often use these devices to isolate specific components based on their magnetic characteristics.

Advantages of Laboratory Magnetic Drum Separators

- High Efficiency: Magnetic drum separators can quickly and effectively separate fine magnetic and non-magnetic particles, making them ideal for small-scale testing and laboratory operations.

- Low Maintenance: The robust design of the drum separator minimizes wear and tear, ensuring minimal downtime in laboratory settings.

- Versatility: These separators can be adapted to different materials and used for various applications, from mineral processing to waste management.

- Continuous Operation: Unlike batch separation processes, magnetic drum separators offer continuous separation, improving throughput and efficiency during testing.

- Cost-Effective: For laboratories that need to perform tests on a small scale before full-scale production or industrial separation, the laboratory magnetic drum separator provides a cost-effective solution for material analysis.

Limitations of Laboratory Magnetic Drum Separators

- Limited to Magnetic Materials: These separators are effective only for materials that exhibit magnetic properties. They cannot separate non-magnetic materials based on other characteristics such as density or size.

- Requires Proper Calibration: To achieve optimal performance, the drum separator must be carefully calibrated according to the material properties and separation goals.

- Scalability: While effective for laboratory-scale operations, the performance of a magnetic drum separator at a larger scale may vary. Additional equipment or modifications may be needed for full-scale operations.

Conclusion

A laboratory magnetic drum separator is an indispensable tool for researchers, engineers, and scientists looking to analyze and separate magnetic materials from non-magnetic ones in a controlled laboratory environment. Its high efficiency, ease of use, and adaptability to different materials make it a valuable asset in industries ranging from mining and recycling to pharmaceuticals and environmental science.

As demand for more advanced and efficient separation technologies grows, the laboratory magnetic drum separator continues to play a critical role in the development of new materials, processes, and innovations across various fields.