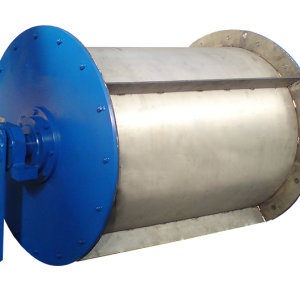

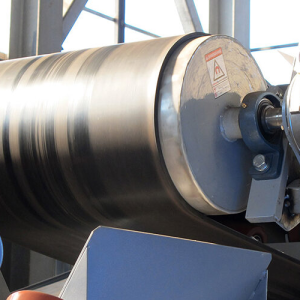

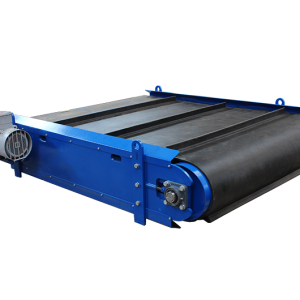

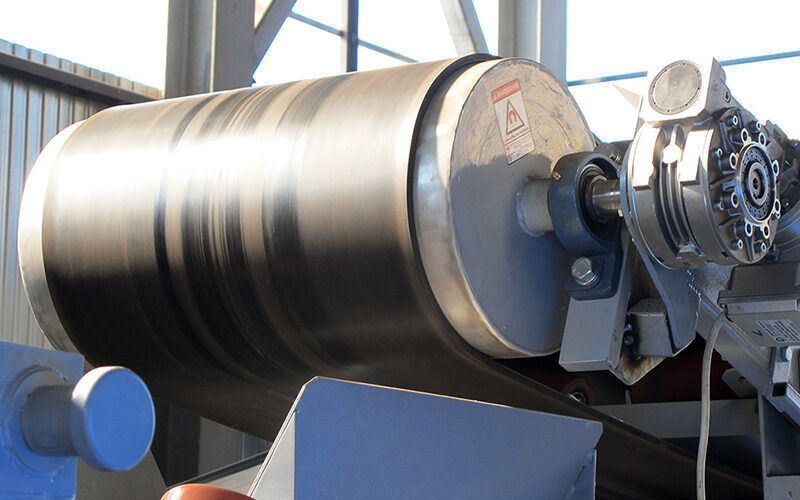

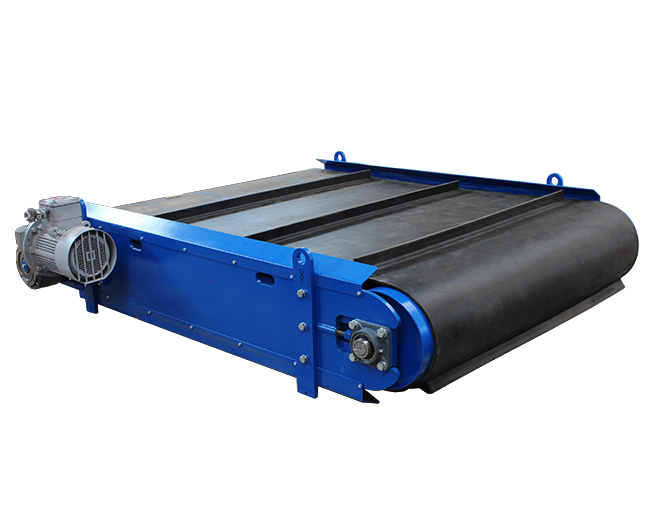

Magnetic pulley tools are essential components in automated material separation systems, designed to extract ferrous contaminants from product flow in conveyor systems. These tools are highly effective in maintaining product quality and protecting processing equipment across various industrial sectors.

Applications and Benefits

Material Handling:

Magnetic pulleys are integrated into conveyor systems to continuously remove ferrous particles from bulk materials. They are widely used in industries such as recycling, mining, and food processing, where clean separation is crucial for efficiency and safety.Waste Management:

These tools play a critical role in waste sorting operations. Magnetic pulleys help separate ferrous metals from mixed waste streams, facilitating more accurate recycling and reducing landfill volumes.Manufacturing:

In manufacturing facilities, magnetic pulleys protect sensitive machinery by capturing metal debris before it enters downstream equipment, minimizing downtime and maintenance costs.

Magnetic pulley tools offer a reliable, low-maintenance solution for continuous metal separation, contributing to improved operational performance, product integrity, and equipment longevity.