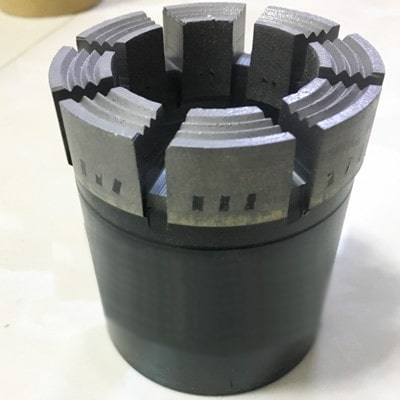

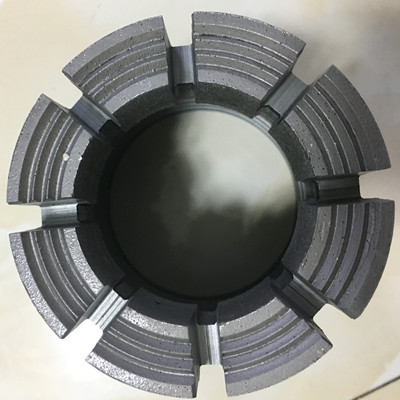

Diamond core drilling tools

Diamond core drilling tools are designed for high-performance drilling in applications such as geological exploration, water conservancy, and building construction. The diamond impregnated bit features synthetic diamonds evenly distributed within a durable metal matrix, ensuring efficient cutting, enhanced wear resistance, and long service life in hard and abrasive formations. These tools are packaged in carton cases and delivered within 5 to 30 days, providing a reliable and timely solution for a wide range of drilling projects.

Technical Data

| Rock Type | Abrasiveness | Rock Hardness | Matrix Hardness | Series. NO |

| Clay,Shale,Siltstone, Cypsum | Medium | Soft | HRC 50 | GV1# |

| Ash Stone, Coal, Argilite,, Volcanics, Sandy Pebble | Very High | Soft | HRC 48-50 | GV1/ GV2 |

| Sandstone, Sandy Shale, Lithoid, Limestone, Limonite Sandstone | Very High | Medium Soft | HRC 45-48 | GV1#/ GV2 |

| Medium-hard, Limestone, Medium-hard Shale, Medium-hard Ash Stone | High | Medium | HRC 40-45 | GV3/ GV4 |

| Marble, Hard Schist, Hard Streak Stone | Medium | Medium | HRC 38-42 | GV5/ GV6/ GV7 |

| Diabase, Andesite, Gneiss | Medium | Medium Hard | HRC 38 | GV6/ GV7 |

| Grandiorite,Limonite | Medium | Medium Hard | HRC 35-38 | GV7/ GV8 |

| Cranite, Basalt, Hard Streak Stone | Medium To Low | Hard | HRC 32-35 | GV8/ GV9 |

| Rhyolite, Crystauize Gneiss, Quartz Porphyry | Medium To Low | Hard | HRC 25-30 | GV9/ GV10 |

| Silicious Stone, Hard Sandstone | Medium To Low | Extreme Hard | HRC 20-25 | GV11/ GV12 |

| Rhyolite, Dense Quartzite, Iron Stone | Low | Ultra Hard | HRC 10-20 | GV12# |

| SIZE | CORE DIAMETER (in) | HOLE DIAMETER | ||

| BQ | 1.433 | 2.345 | ||

| NQ | 1.875 | 2.965 | ||

| HQ | 2.500 | 3.763 | ||

| PQ | 3.345 | 4.805 | ||

| NQ3, NQTT | 1.775 | 2.965 | ||

| HQ3, HQTT | 2.406 | 3.763 | ||

| PQ3, PQTT | 3.270 | 4.805 |