There are different types of core barrel from different systems and in different standards, with the choice of one or the other depending on:

- the characteristics of the formation to be drilled.

- depth of the drilling

- drilling diameter

- drill rig features

The most common types of core barrels are manufactured under ISO 3552-1992 (single B, double T2, etc.) and ISO 10097-1: 99 (cable line). In the industry there are types of core barrels that are not standardized and that are used worldwide on a regular basis (for example, T6, T6S, Geo-line, etc.).

Drilling with any of the core barrels (conventional, ISO 3552-1992) is done by adding rods as the drilling progresses. When the core barrel is full it is necessary to remove the entire drill string (all the rods and the core barrel), at best, every 3 meters. To continue it is necessary to reintroduce the entire drill string by adding one more rod. This means that as the depths of extraction and introduction are advanced in depth is time that is not being drilled, therefore the cost per meter of drilling carried out increases significantly.

- Single tube core barrel type B

- T2 core barrel

- TT core barrel

- TTR core barrel

- T6, T6 Triplex and T6 Triplex F/D core barrel Ø:76/86/101

- T6, T6 Triplex and T6 Triplex F/D core barrel Ø: 116/131/146

- T6S core barrels Ø:76/861/101

- T6S core barrel Ø: 116/131/146

- Conventional drill rods

Wire-line Drilling System

This double tube core drilling system is the one used when the depth makes the drilling times very long using conventional system, and the drilling speed is compensated with respect to the higher cost of the materials of the wire-line system. Today, no operator plans to drill with conventional systems at depths greater than about 100 m. The wire-line is, without a doubt, the most widely used in conducting mining research or deep geotechnical surveys (e.g. tunnels).

With this system it is quite common to reach depths of 1,300-1,600 meters, although the operating limit of depth in favorable conditions and hastening its possibilities is close to 2,500 meters.

The system uses specific elements for wire-line and basically consists of:

- Wire-line core barrel BWL

- Wire-line core barrel NWL

- Wire-line core barrel HWL

- Wire-line core barrel PWL

- Geo-Line 146S Core Barrel

- CSK-146 core barrel

-

Overshot BWL

-

Overshot NWL-HWL-PWL

-

BWL-NWL-HWL-PWL horizontal drilling Overshot

-

BWL-NWL-HWL-PWL short Overshot

-

Overshot Geo-Line 146S

-

Overshot CSK-146

-

Wire Line drill rods

Drilling Accesories

WATER SWIVELS

Through this element, the circulation fluid is injected into the borehole so that it reaches the cutting tool, cools it and in turn elevates the cutting produced during drilling. It should not be used for the extraction of the drill string that is the Hoisting Plug function.

HOISTING PLUG

This tool is simply an element for the extraction of the drill string from the hole. On one end it is attached to the winch cable and on the other it is threaded to the rod.

AUTOMATIC TRIP HAMMER

The automatic trip hammer is designed for driving the Standard Penetration Test. (SPT)

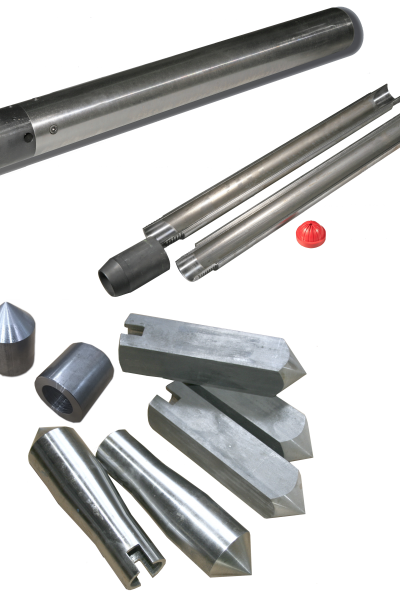

FISHING TOOLS

In drilling, we call fishing tools a series of tools intended to recover materials that, due to breakage or drilling problems, remain inside the borehole and must be extracted.

Among the most common we can include recovery cones, recovery bells and pipe cutters.

LIGTH FULL GRIP WRENCH

Samplers and Dynamic Penetration Test

SAMPLERS

In general, most of the samplers consist of:

Head with connection to the rod (some with valve)

Sample receiver tube (with or without inner tube)

Shoe

There are a wide variety of types of samplers, but the most used are the Sectioned, Shelby and SPT (Standard Penetration Test).

- Windowless samplers

- Sectioned samplers

- Split-Barrel/SPT samplers

- Shelby samplers

PENETRATION EQUIPMENT

The most widely used dynamic penetration tests are governed by UNE-EN ISO 22476-2: 2008 and UNE-EN ISO 22476-2: 2008 / A1: 2014 (modification 1) and within this standard the usual system follows the DPSH guidelines -B, among other reasons because the driving device also complies with the regulations for conducting SPT tests and is usually mounted on geotechnical drilling machines.

- Dynamic Penetration Test

Diamond and Carbotec Core Bits

This is the cutting element and is decisive in the execution of a drilling. We can say that it is one of the most important elements on the drill string. if the core bit cuts well, difficulties and problems in the drilling decrease remarkably. A good one choice of cutting tool allows us to make a work with better results in the quality of the sample, in the economic part and in the functionality of the drilling.

Casings

RODS

It is the tool transmitter of rotation and thrust to the cutting tool. It must be hollow to allow the circulation of the drilling fluid to reach the front of the core barrel, that is, to the cutting tool (core bit). In essence, these are hollow bars with a male thread at one end and a female thread at the other end, so that they allow the union of several rods one after the other and, at the end, their connection to the core barrel.

CASINGS

Casing pipes are not for drilling. The casing pipes are to be installed inside a previously drilled borehole and always with a smaller diameter.

- Metric casings

- W-WT casings